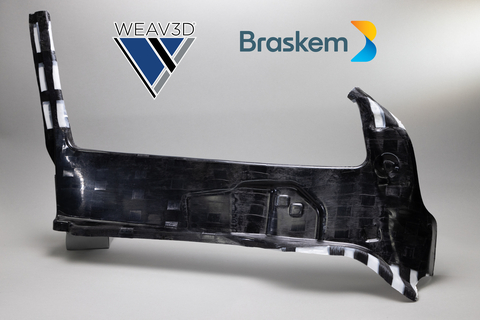

This solution combines Braskem’s polypropylene sheets with WEAV3D lattice technology to address new structural and automotive applications requiring high-strength, lightweight material solutions

Braskem to present its PP solutions with WEAV3D lattice technology at the 2023 SPE® TPO Global Automotive Conference in Detroit, October 1-4

Braskem (BM&FBOVESPA: BRKM3, BRKM5 and BRKM6; NYSE: BAK; LATIBEX: XBRK), the largest polyolefins producer in the Americas as well as a market leader and pioneer producer of biopolymers on an industrial scale, today announced a novel demonstrator of Braskem’s polypropylene (PP) in combination with WEAV3D Inc., an advanced manufacturing and materials startup, leveraging WEAV3D’s thermoplastic composite lattice technology to enhance the performance of PP for structural and automotive material applications.

This press release features multimedia. View the full release here: https://www.businesswire.com/news/home/20230928754765/en/

Beltline Stiffener (Photo: Business Wire)

The WEAV3D lattice technology enables lightweight PP parts to replace materials like steel, increasing PP’s use in automotive applications by balancing improvements in performance, weight, and cost. The combination of Braskem PP sheets with WEAV3D’s Rebar for Plastics will allow Braskem to compete in new structural material end-markets.

“We’re excited to offer our clients new innovations and partnerships around high-performance polypropylene materials utilizing the WEAV3D lattice technology. As the automotive industry continues to roll out new electric vehicle designs, it requires automakers to re-think the vehicle design with cutting-edge performance materials. With significant improvements in lightweighting, reduced costs, and higher material efficiency, combining Braskem’s PP portfolio with WEAV3D composite lattices provides a ‘win-win’ in terms of enhanced material performance and a more sustainable environmental impact, including the integration of natural fiber options,” Amanda Zani, Technology Platform Manager, Braskem.

Benefits of using WEAV3D’s Rebar for Plastics® and Braskem Polypropylene vs. conventional composite organosheet:

- LIGHTWEIGHT – Reduces sheet blank weight by ~50% and final part weight by ~20%

- COST EFFECTIVE – Reduces costs by ~50%

- EFFICIENT – Increases sheet yield from 25% to 45% by weight, resulting in a 63% reduction in trim waste

“Braskem has been a fantastic partner throughout this project and really demonstrated a strong commitment to sustainable materials innovation,” says Chris Oberste, President of WEAV3D. “Leveraging Braskem’s diverse polypropylene portfolio and deep technical expertise, we worked collaboratively with the Braskem team to identify the right combination of Braskem PP and reinforcing lattice material in order to minimize cost and maximize performance, while achieving formability and sustainability goals.”

Braskem will exhibit at the Society of Plastics Engineers (SPE) TPO Global Automotive Conference in Troy, Michigan from October 1-4, 2023, where they will meet with attendees to discuss the benefits of Braskem and WEAV3D’s lattices with leading OEMs, suppliers, and the entire polyolefins value chain community.

For more information, please click here.

Gustavo Lombardi, Braskem’s Director of Business Development, will be a Keynote Speaker at the 2023 TPO Global Automotive Conference presenting “Reducing Carbon Footprint with Performance: The Role of Bio-Based Plastics in Mitigating Climate Change” at 9:15 am on Monday, October 2, 2023.

ABOUT WEAV3D Inc.

Headquartered in metro Atlanta, Ga., WEAV3D is an innovator in composite materials, manufacturing processes, and processing equipment, having spun out of the Georgia Institute of Technology in 2017. WEAV3D’s patented composite forming technology integrates weaving and composite consolidation into an automated, continuous process that reduces waste, cycle times and material handling costs. When combined with injection overmolding, thermocompression, or thermoforming, this novel Rebar of Plastics® approach improves part stiffness and strength while minimizing weight, enabling new innovations in the automotive and construction markets at a fraction of the cost and cycle time associated with traditional composite manufacturing.

ABOUT BRASKEM

With a strategy centered on people and sustainability, Braskem is engaged in contributing to the value chain to strengthen the Circular Economy. Braskem’s almost 9,000 team members dedicate themselves every day to improving people's lives through sustainable solutions in chemicals and plastics. With its corporate DNA rooted in innovation, Braskem offers a comprehensive portfolio of plastic resins and chemical products for diverse industries, such as food packaging, construction, manufacturing, automotive, agribusiness, health, and hygiene, and more. With 40 industrial units in Brazil, the United States, Mexico, and Germany, Braskem exports its products to clients in over 70 countries.

Braskem America is an indirect wholly owned subsidiary of Braskem S.A. headquartered in Philadelphia. The company is the leading producer of polypropylene in the United States, with five production plants located in Texas, Pennsylvania, and West Virginia, an Innovation and Technology Center in Pittsburgh, and a New Renewable Innovation Center in Boston focused on leveraging groundbreaking developments in biotechnology and advanced materials. For more information, visit www.braskem.com/usa.

Braskem on English social media:

www.facebook.com/BraskemGlobal

www.linkedin.com/company/braskem

www.twitter.com/Braskem

View source version on businesswire.com: https://www.businesswire.com/news/home/20230928754765/en/

Contacts

For press information:

Braskem North America

Stacy Torpey

Communications Director

1 (215) 841 3194

stacy.torpey@braskem.com